[ad_1]

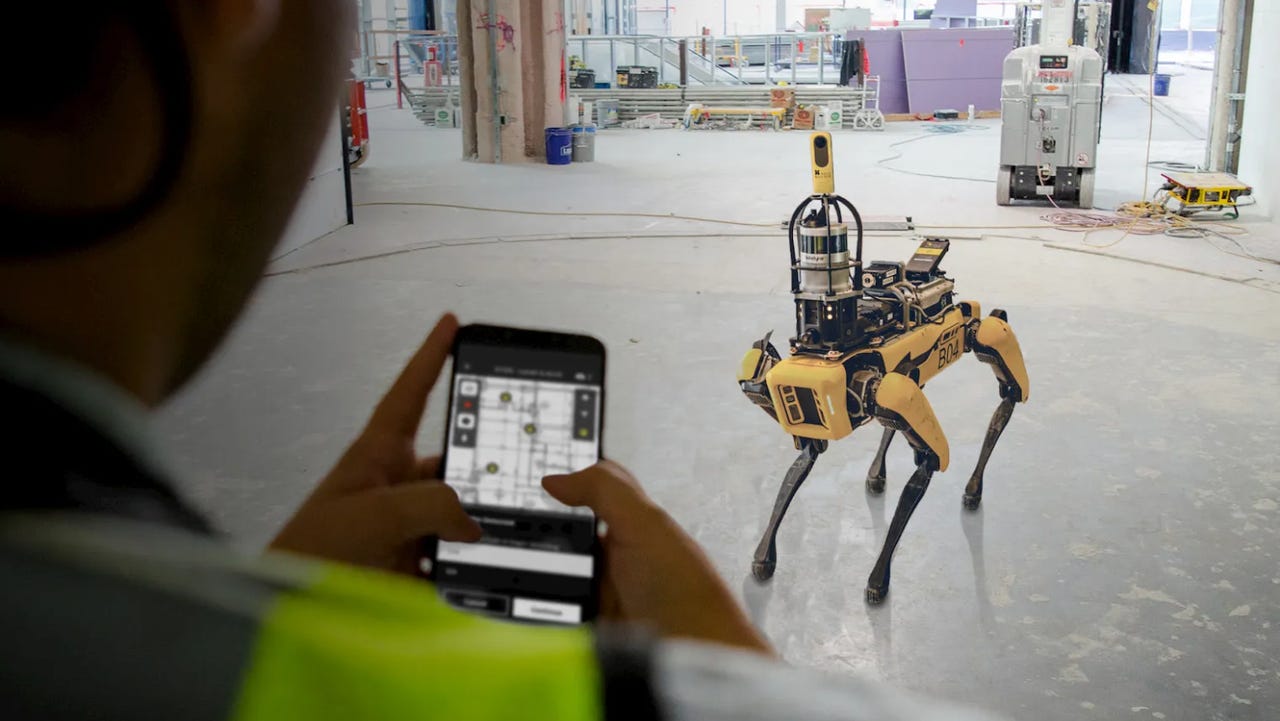

If you’ve ever come across a video of a robot dog performing amazing tricks, then you’ve most likely watched Boston Dynamics’s robot dog Spot in action.

Despite being the subject of some entertaining videos, the agile mobile robot also has important real-world, enterprise applications in sectors such as manufacturing, construction, and research.

Also: What the ‘new automation’ means for technology careers

Spot is used by major companies such as National Grid, BP, NASA JPL, and more for its advanced capabilities, which include autonomous inspections, substance detection, data collection, and even physical strength.

On Wednesday, Boston Dynamics unveiled Spot 3.3, a collection of software and hardware updates that help improve the robot dog’s ability to perform critical industrial tasks.

“We’ve introduced a bunch of features around making the robot a better co-worker in your industrial facility,” said Zack Jackowski, chief engineer for Spot, speaking with ZDNET.

Some of the updates Spot has received are behavioral enhancements, including the ability to detect moving objects such as people or forklifts.

“I know that sounds like kind of low-hanging fruit, but it’s one thing to make a demo of a thing working, and it’s a pretty big other thing to make an industrial-quality product that does something like that and deploy it in a real customer site,” said Jackowski.

Also: Boston Dynamics robot dog can answer your questions now, thanks to ChatGPT

Spot also got a boost in its ability to walk safely in slippery environments with wet floors, and to catch itself when it slips.

This feature, like the rest of the new upgrades, was created in response to customer feedback.

“We get just this constant stream of customers coming in and saying, ‘Hey, it’d be really cool if the robot could do this for me,’ and we go off, and we think about it, and boom, it might be there and the next release,” said Jackowski.

For example, Jackowski shared that Boston Dynamics’s customer, Anheuser Busch, often has wet floors at its facilities due to the floor sanitation processes that take place at breweries.

Also: Here’s why most business leaders would let a robot make their decisions

As a result, the Boston Dynamics team put in a ton of work to make sure that Spot is able to walk in this challenging environment.

“That’s what’s so much fun about working on these mobile robots is, you know, you can make a piece of hardware, and just keep on making it capable of doing new things forever,” said Jackowski.

Spot has also received upgrades to improve its inspection workflows.

Spot’s inspection abilities are crucial to its work in industry, as it can help companies detect issues early. For example, Spot is equipped with thermal inspection, which can detect hot spots on machines or electrical conductors, and gauge reading, which can read and inspect analog gauges from afar.

Also: AI could automate 300 million jobs

The robot is now getting a software update that adds multiple, simultaneous inspection types, including a fully end-to-end thermal inspection workflow.

Gauge reading was upgraded through a partnership with Levatas, which gives Spot a gauge reading computer vision add-on. Acoustic imaging, which allows Spot to detect abnormal noise readings, is also fully integrated into Spot with this latest release.

Scout, Spot’s remote-inspection software — where all the mission editing, scheduling, and actionable data can be found — has new features, including a dashboard where customers can review their robot’s progress in operations.

Lastly, Spot’s hardware has been upgraded to include an audio and visual signaling system to improve the robot’s relationship with the people in its surrounding environment.

Also: The best AI chatbots

The new audio-visual system includes safety lights located around the robot, a safety buzzer, and a speaker, according to the release.

All of the features will be available to customers who have the enterprise version of the robot. Upgrade packages are also available for customers who bought early versions of Spot to make sure they have access to the most up-to-date robot and features.

Although these updates might seem like a collection of smaller features, they are all part of a bigger plan.

“It’s all in pursuit of this big vision of these little robot inspectors wandering around your factory, and just making sure that everything is always working perfectly all the time,” said Jackowski.

In a few years, these robot dogs will be able to understand everything that’s happening around them, he added.

[ad_2]

Source link