Choosing the right packaging equipment is essential for efficiency, output quality, and long-term productivity. Whether a business is packaging small retail goods or managing high-volume production lines, selecting the appropriate POF shrink film machine significantly impacts operational speed and cost control. Because shrink packaging needs vary across industries, understanding production volume and matching it with the correct equipment ensures consistent results and a smoother workflow.

Why Production Volume Determines Machine Selection

Production volume is the first factor to consider when evaluating shrink packaging equipment. Low, medium, and high-volume operations each require different levels of automation, sealing strength, and film handling capabilities. If the equipment is too slow for demand, bottlenecks form; if it’s too advanced for your needs, resources go underutilized.

Avoiding Undercapacity And Overcapacity

Selecting a pof shrink film machine with insufficient speed forces workers to compensate manually, increasing labor costs. Conversely, choosing a machine designed for far higher volume than needed drives up energy usage, maintenance costs, and upfront investment without offering real value.

Ensuring Consistent Seal And Shrink Quality

Production speed affects shrink quality. The right machine maintains uniform heat application and sealing precision, ensuring each package looks crisp and professional without film wrinkling or tearing.

Matching Low-Volume Production With Manual Or Semi-Automatic Machines

Companies with lower output—often small businesses, startup operations, or seasonal producers—benefit from simpler equipment.

Manual Shrink Systems

Manual systems use separate sealing and shrink equipment, giving operators full control over packaging speed. They are ideal for businesses running fewer than 500 packages per day.

Benefits include:

- Lower upfront cost

- Flexible operation

- Simple training requirements

- Suitable for irregular product shapes

Semi-Automatic POF Shrink Film Machines

Semi-automatic models increase speed while still allowing operator involvement. They handle tasks such as film feeding or sealing at a controlled pace, making them ideal for businesses transitioning from manual to scalable operations.

These machines help small operations maintain consistent quality without overwhelming their workflow.

Medium-Volume Operations: The Versatility Of L-Bar Sealers And Integrated Systems

Companies producing between 500 and 3,000 packages daily often face the challenge of scaling efficiently. This is where mid-level solutions shine.

L-Bar Sealer Systems

L-bar sealers paired with a POF shrink film machine offer balanced automation. The sealing bar forms clean, strong seals around packages, while a heat tunnel shrinks film evenly.

Advantages:

- Higher throughput than manual systems

- Ideal for uniform product sizes

- Adjustable speed and temperature controls

- Lower film waste and higher precision

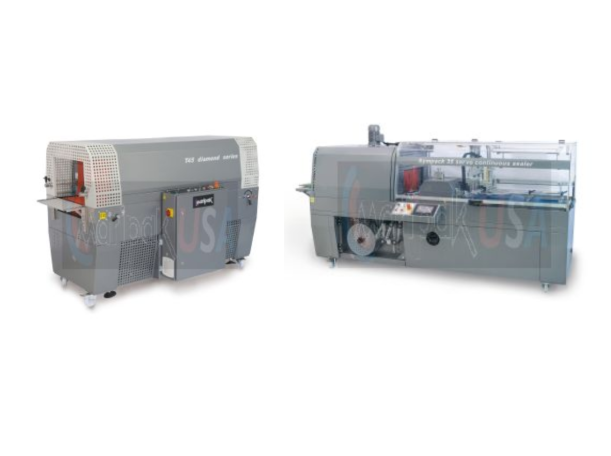

Integrated Seal-And-Shrink Units

These systems combine sealing and shrinking into one continuous process, improving efficiency for growing businesses. They reduce handling time and enhance consistency, making them ideal for packaging consumer goods, cosmetics, food items, or printed materials.

High-Volume Production: Fully Automatic Shrink Systems

Large-scale production—3,000+ packages daily—requires fully automated shrink equipment designed for nonstop operation.

Continuous-Motion Automatic Machines

These advanced systems handle sealing, cutting, and shrinking in one automated flow. Pairing them with a high-speed pof shrink film machine ensures maximum output efficiency.

Key features include:

- Rapid throughput

- Conveyor-driven automation

- Minimal operator involvement

- High precision for uniform packages

They excel in environments where speed, consistency, and long-term durability are essential.

Automatic Side Sealers

Side-seal equipment is ideal for longer products or operations that require continuous packaging without downtime. Their high-speed mechanisms quickly adapt to different film widths and product types.

Conclusion

The right pof shrink film machine depends on a clear understanding of production volume, product variation, available space, and desired speed. Whether your business requires a manual setup for small batches or an automated system for high-output workflows, aligning machine capabilities with your operational demands guarantees better performance and long-term efficiency. And for businesses expanding into more complex packaging setups, integrating a reliable heat sealing machine provides additional support for consistent, professional results across all product lines.